Green Design Combines with Advanced Technology in Modern Manufacturing Facilities.

In today's fast-changing industrial landscape, the convergence of sustainable design and smart technology is transforming how products are created and manufactured. As environmental concerns take center stage, businesses are more and more aware of their duty to integrate sustainability into every aspect of their operations. Such a change is not only a response to consumer demand but also a requirement for long-term viability in a resource-constrained world. The idea of “smart factories” plays a crucial role in this transformation, where advanced technologies are smoothly woven into the fabric of production processes, resulting in innovative design solutions that prioritize environmental stewardship.

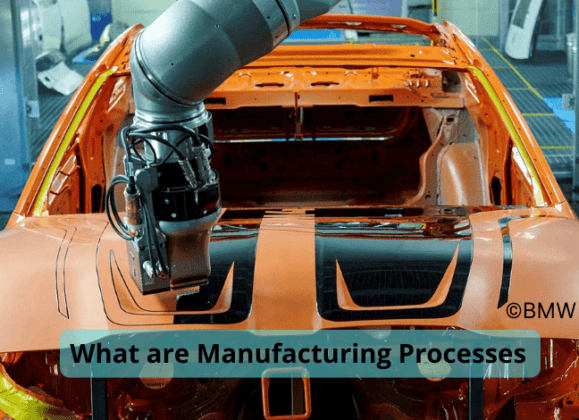

Smart factories utilize robotics, big data, and artificial intelligence to optimize manufacturing processes, reducing waste and enhancing efficiency. This tech-based backbone supports a new approach to product design that emphasizes sustainability from the ground up. By leveraging smart technologies, manufacturers can create products that are not only high in quality but also reduced in their ecological footprint. This fusion of sustainable practices and cutting-edge technology is driving a new age of manufacturing where the potential for expansion aligns with the necessity of preserving our planet for coming generations.

Incorporating Sustainability in Design

In the area of product design and manufacturing, implementing sustainability has become an integral focus for contemporary factories. Designers are increasingly prioritizing eco-friendly materials and processes right from the conceptual stage. By selecting renewable resources, biodegradable materials, and non-toxic chemicals, products can be created with a lower environmental impact, setting new industry standards for sustainability.

Furthermore, the life cycle of a product plays a significant role in its design. Sustainable design considers the complete lifecycle, from raw material extraction up to production, usage, and final disposal. Factories are embracing design strategies that enhance durability and promote repairability, which can reduce waste and prolong product lifespan. This holistic approach not only conserves resources but also resonates with consumers who are more and more demanding responsible manufacturing practices.

Cooperation between designers, engineers, and sustainability experts is vital for successful integration. Leveraging smart technologies can simplify this process by facilitating real-time monitoring of material usage and energy consumption during production. These innovations allow for adjustments to be made on-the-fly, which optimizing efficiency and reducing waste. Ultimately, merging sustainable practices with smart technology leads to a more sustainable manufacturing sector that addresses the needs of both the planet and consumers.

Smart Technology in Manufacturing

The adoption of advanced technology in manufacturing is transforming conventional processes into highly efficient systems. Sophisticated sensors, automation, and data analytics enable instantaneous monitoring of production lines, enabling manufacturers to react swiftly to fluctuations and demands. This linked ecosystem optimizes resource allocation and minimizes waste, thereby driving down costs while boosting product quality. By utilizing smart technology, factories can achieve a degree of precision and adaptability that was not possible before.

Additionally, the use of the Internet of Things has further transformed manufacturing practices. Machines and equipment can interact with each other and with core management systems, providing invaluable data that can be analyzed for continuous improvement. Predictive maintenance powered by smart sensors helps in anticipating breakdowns, minimizing downtime, and extending the lifespan of machinery. This preventive approach not only boosts productivity but also promotes a more green production cycle by making sure that resources are used effectively.

The integration of smart technology with eco-conscious practices in product design and manufacturing cultivates a new era of industrial innovation. Factories can now design processes that prioritize environmental responsibility without sacrificing on efficiency. By employing renewable energy sources, waste recycling, and green materials, manufacturers are not just enhancing their bottom line but also dedicated to a greener planet. This interaction between smart technology and sustainable design is essential in shaping the future of manufacturing.

Case Studies: Success Stories

An exceptional success story is the introduction of a advanced manufacturing system by a leading automotive company. By incorporating IoT sensors throughout their assembly lines, they were able to monitor energy consumption in actual time and detect inefficiencies. This analytics-based approach not only lowered their carbon footprint but also improved the production process, leading to a considerable decrease in waste materials. The company's commitment to sustainable product design and smart technology has resonated with consumers, boosting their brand reputation and increasing sales.

Additionally, striking example comes from a furniture manufacturer that embraced sustainable practices through smart technology. By leveraging advanced robotics and AI in their production process, they reduced the use of non-renewable materials while enhancing the use of reclaimed wood. This groundbreaking approach not only preserved the environment but also enabled unique, customizable designs tailored to customer preferences. The combination of sustainability and smart technology allowed this manufacturer to stand out in a competitive market, illustrating the value of eco-conscious product design.

In conclusion, a worldwide electronics company has effectively merged sustainability with smart technology in the production of eco-friendly gadgets. Their factories utilize renewable energy sources and prioritize recycling of materials. By using smart manufacturing techniques, they can create products that are easier to take apart and recycle, greatly contributing to a circular economy. This initiative not only fulfills consumer demand for sustainable electronics but also creates a benchmark in the industry, proving that smart factories can pave the way in responsible manufacturing and innovative product design.